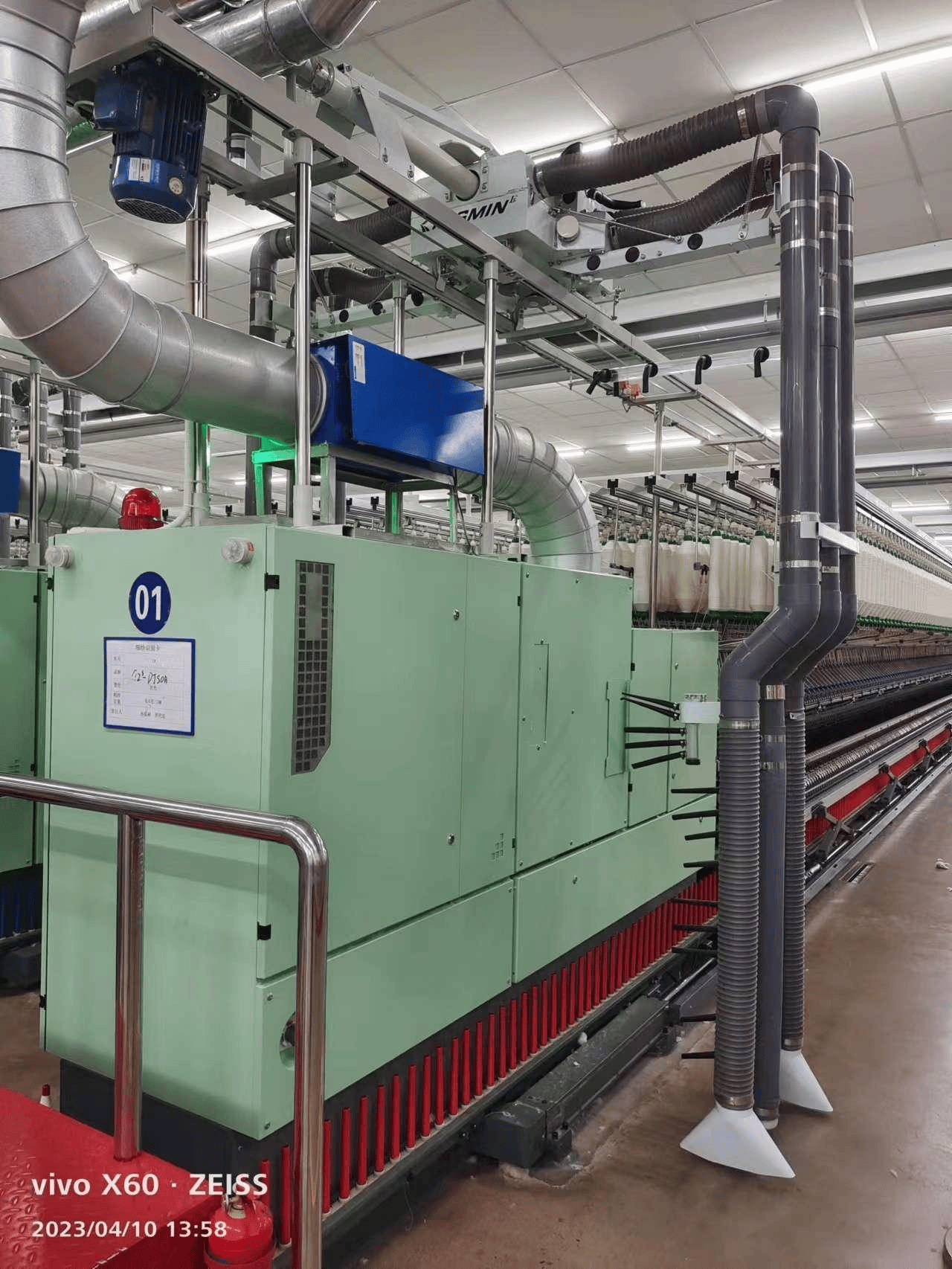

The new blow-suction cleaning machine offers significant advantages in material selection, processing technology, and quality control, as detailed below:

Material and Processing Technology Advantages

Drive Wheel, Driven Wheel, and Differential Diameter Wheel: Made from alloy steel, the surfaces are electroplated for rust resistance and wear resistance. The processing technology uses CNC equipment for precision machining, ensuring high accuracy. They are tested with imported dynamic balancing instruments to ensure stable operation after assembly. The product has strong consistency, high interchangeability of parts, and is easy to maintain and replace.

Impeller: Made from high-quality aluminum with a smooth surface that reduces the likelihood of yarn tangling. The impeller is processed with CNC technology and tested with imported dynamic balancing equipment, ensuring high assembly precision, good fit, and excellent balance, which effectively extends the lifespan of bearings and equipment.

Structural Design and Energy Efficiency Advantages

Main Body Shell: Optimized based on fluid dynamics principles, designed for energy savings and high efficiency, and patented. The matching motor adopts national grade 2 energy-efficient products, making the blow-suction cleaning machine more efficient and energy-saving during operation, with better cleaning performance.

Drafting Area: Equipped with a 90?? rotatable multi-point nozzle, which automatically rotates when the blowing and suction air reaches the front and rear of the spinning machine, preventing collisions. The dedicated fixed-point nozzle for drafting more effectively cleans critical areas in the spinning process, reducing the cleaning workload for employees, lowering yarn defects, and improving yarn quality.

Self-Cleaning System and Energy-Saving Design

Main Unit Self-Cleaning System: Utilizes a self-developed energy-saving cleaning system that performs self-cleaning only at the front and rear, and only cleans the equipment in between, improving cleaning efficiency while saving energy.

Self-Suction Cotton Air Gate: Features an outward-opening door structure, avoiding the problems of spring fatigue and damage seen in traditional inward-opening door structures, ensuring stable performance and reducing maintenance costs and workload.

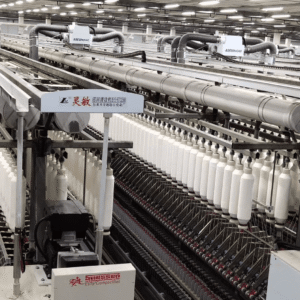

Nozzle and Cotton-Suction System Advantages

Nozzle: Made entirely from silicone, offering flexibility, durability, and resistance to aging, ensuring reliability for long-term use.

Centralized Cotton-Suction Unit: Uses a high-efficiency centrifugal fan with low energy consumption and excellent cotton-suction effect. The unit’s housing adopts a two-stage filtration structure, effectively filtering short fibers and impurities, preventing issues like poor filtering performance and overflow seen in traditional single-layer filters.

Quality Advantages

High Precision Processing and Testing: All critical components are processed with CNC equipment and tested with imported dynamic balancing instruments to ensure high precision and stability.

Energy-Saving and High Efficiency: Optimized design and high-efficiency motors ensure the blow-suction cleaning machine operates more efficiently, with better cleaning results.

Durability and Easy Maintenance: Materials are selected for rust resistance, wear resistance, and anti-aging, and the structural design reduces maintenance requirements, lowering equipment maintenance costs and workload.

Summary:

The new blow-suction cleaning machine offers significant advantages in material selection, processing technology, structural design, and energy efficiency, ensuring high precision, high performance, long lifespan, and low maintenance costs. Its unique design and patented technology make it superior to traditional products in cleaning effectiveness, energy efficiency, and equipment stability, effectively improving production efficiency and reducing operating costs.