Role and Importance of the Coarse Yarn Warehouse Blow-Suction Cleaning Machine

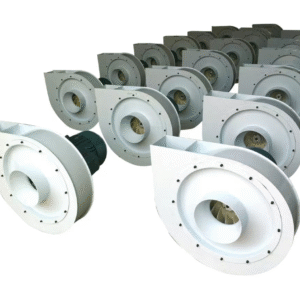

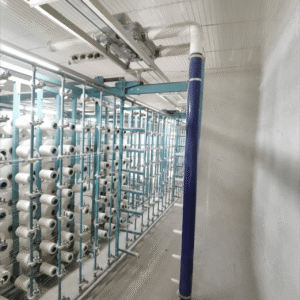

The coarse yarn warehouse blow-suction cleaning machine is a key auxiliary device in the automation of textile production, mainly used for continuous blow-suction cleaning of the high-altitude coarse yarn warehouses to ensure that no flying waste or short fibers accumulate on the warehouse surfaces. Its core functions include:

Continuous Cleaning: By providing uninterrupted circulating airflow, it effectively removes flying waste and short fibers from the surface of the yarn warehouse, maintaining a clean environment.

Reducing Safety Hazards: Accumulated flying waste and short fibers can lead to fire hazards or equipment malfunctions. The blow-suction cleaning machine reduces these risks by timely cleaning.

Improving Product Quality: A clean yarn warehouse environment reduces yarn contamination, thus improving the quality of the final product.

Supporting Automated Production: As part of an automated system, this equipment reduces manual intervention, enhancing production efficiency.

Key Features:

Automated Operation: The device performs automatic circulating cleaning, reducing the need for manual intervention.

Efficient Cleaning: Strong airflow removes flying waste and short fibers, ensuring a clean warehouse surface.

Safe and Reliable: Reduces fire hazards and equipment failures, ensuring production safety.

Increased Efficiency: Reduces downtime and improves production efficiency.

Application Scenarios:

Coarse Yarn Warehouse: Used for cleaning coarse yarn warehouses to prevent the accumulation of flying waste and short fibers.

High Automation Production Lines: Suitable for highly automated spinning production lines, reducing the need for manual cleaning.

Summary:

The coarse yarn warehouse blow-suction cleaning machine plays a vital role in textile production. Through automated cleaning, it not only enhances production efficiency and product quality but also reduces safety hazards, making it an indispensable piece of equipment in modern spinning production.