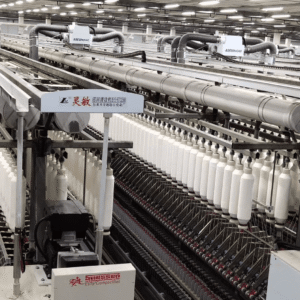

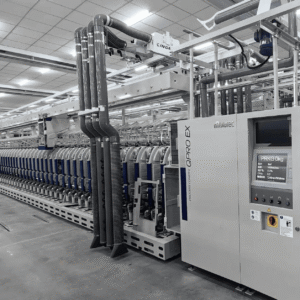

LM-6 Series Energy-Saving Retrofit for Coarse Yarn Machines

The coarse yarn machine processes slivers into coarse yarn by stretching and twisting. During this process, short fibers and flying waste are generated. Most of the coarse yarn machines currently in use employ a circulating blow-suction fan to collect waste from the stretching area, while using a nozzle to blow flying waste from the machine surface into the cotton suction main duct. A 3KW (or 4KW) cotton-suction fan, driven by the machine’s front end, sucks the flying waste into the cotton collection box at the front of the machine.

Energy-Saving Retrofit Plan:

Remove the original dust-collecting fan and main duct, and install a new storage bin.

Use the circulating blow-suction fan to blow short fibers and flying waste into the storage bin.

Utilize the existing cleaning rotating shaft drive conveyor belt of the coarse yarn machine (or add a 60W reduction motor) to transport the accumulated waste in the storage bin to the storage box (the storage box is available in both manual and self-suction cotton versions).

The workers should clean the drive shafts at both ends and the accumulated waste in the cotton storage box once per shift.

For up to 4 coarse yarn machines, the original cotton-suction fan at the machine head can be used for centralized cotton suction. For 5-10 machines, a new 4KW centralized cotton-suction unit and conveyor belt system will be required to collect the accumulated waste.