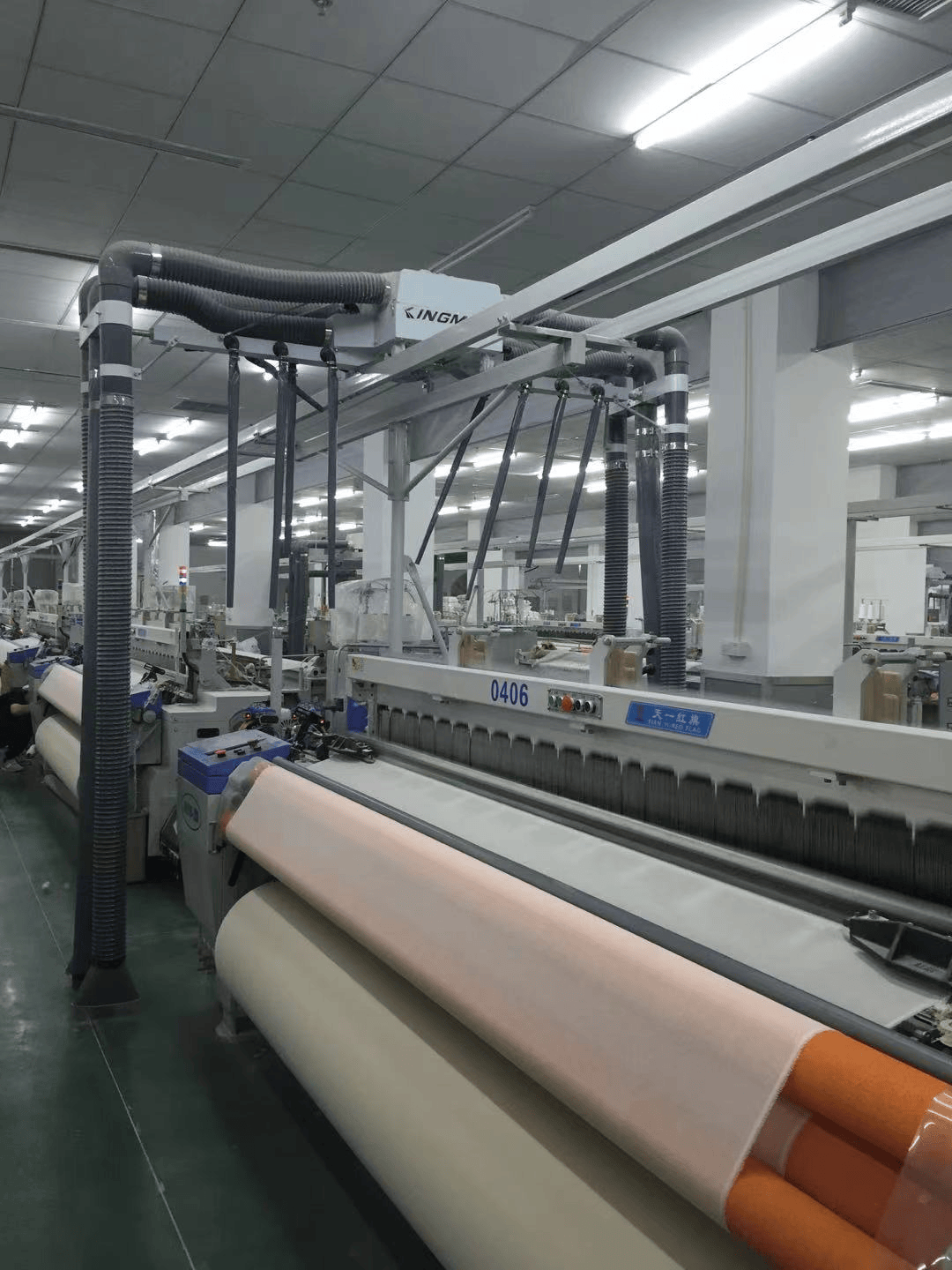

Blow-Suction Cleaning Machine for Weaving Machines:

The blow-suction cleaning machine for weaving machines is a highly efficient cleaning device designed specifically for the textile industry, aiming to solve the flying waste problem generated by weaving machines, especially air-jet looms, during the production process. Below are the main functions and application advantages of the equipment:

Efficient Cleaning:

Cleaning Scope: The blow-suction cleaning machine can effectively clean key areas of the loom, including the warp beam, heald frame, and reed. These areas are prone to accumulate flying waste, which can lead to yarn breakage and fabric defects, while also affecting the loom’s production efficiency.

Cleaning Method: Through the dual action of blowing and suction, the equipment can effectively remove flying waste, preventing it from adhering to machine parts.

Reducing Yarn Breakage and Machine Downtime:

Protection of Warp and Weft Yarn: Flying waste adhering to the heald frame and reed increases friction on the yarn, leading to breakage. The blow-suction cleaning machine effectively reduces breakage and downtime by promptly removing flying waste.

Improved Production Efficiency: Reducing yarn breakage and machine downtime means the loom can operate continuously, thereby improving production efficiency.

Improved Fabric Quality:

Reducing Fabric Defects: Flying waste that sticks to the yarn can cause fabric defects, impacting product quality. Regular cleaning by the blow-suction cleaning machine effectively reduces fabric defects and enhances fabric quality.

Labor Cost Savings:

Reducing Labor Intensity: Traditional manual cleaning methods are not only inefficient but also labor-intensive. The blow-suction cleaning machine can automatically perform cleaning tasks, reducing dependence on cleaning workers and decreasing labor intensity.

Automated Operation: The machine is equipped with automation features, such as automatic return when encountering obstacles, further reducing the need for manual intervention. Intelligent Features:

Automatic Return When Obstructed: The loom blow-suction cleaning machine is typically equipped with an intelligent sensing system, allowing it to automatically return when encountering obstacles, preventing equipment damage and ensuring the continuity and safety of the cleaning process.

Strong Adaptability

Multiple Models Adaptation: The loom blow-suction cleaning machine can be customized according to the characteristics of different looms, adapting to various models of jet looms and other types of weaving machines.

Energy-Efficient and Environmentally Friendly:

High Energy Efficiency Ratio: Modern loom blow-suction cleaning machines are usually designed with energy-saving features, enabling efficient cleaning while reducing energy consumption, meeting environmental protection requirements.

Application Scenarios:

Jet Looms: Due to the high-speed operation of jet looms, the issue of flying waste is particularly prominent, and the blow-suction cleaning machine