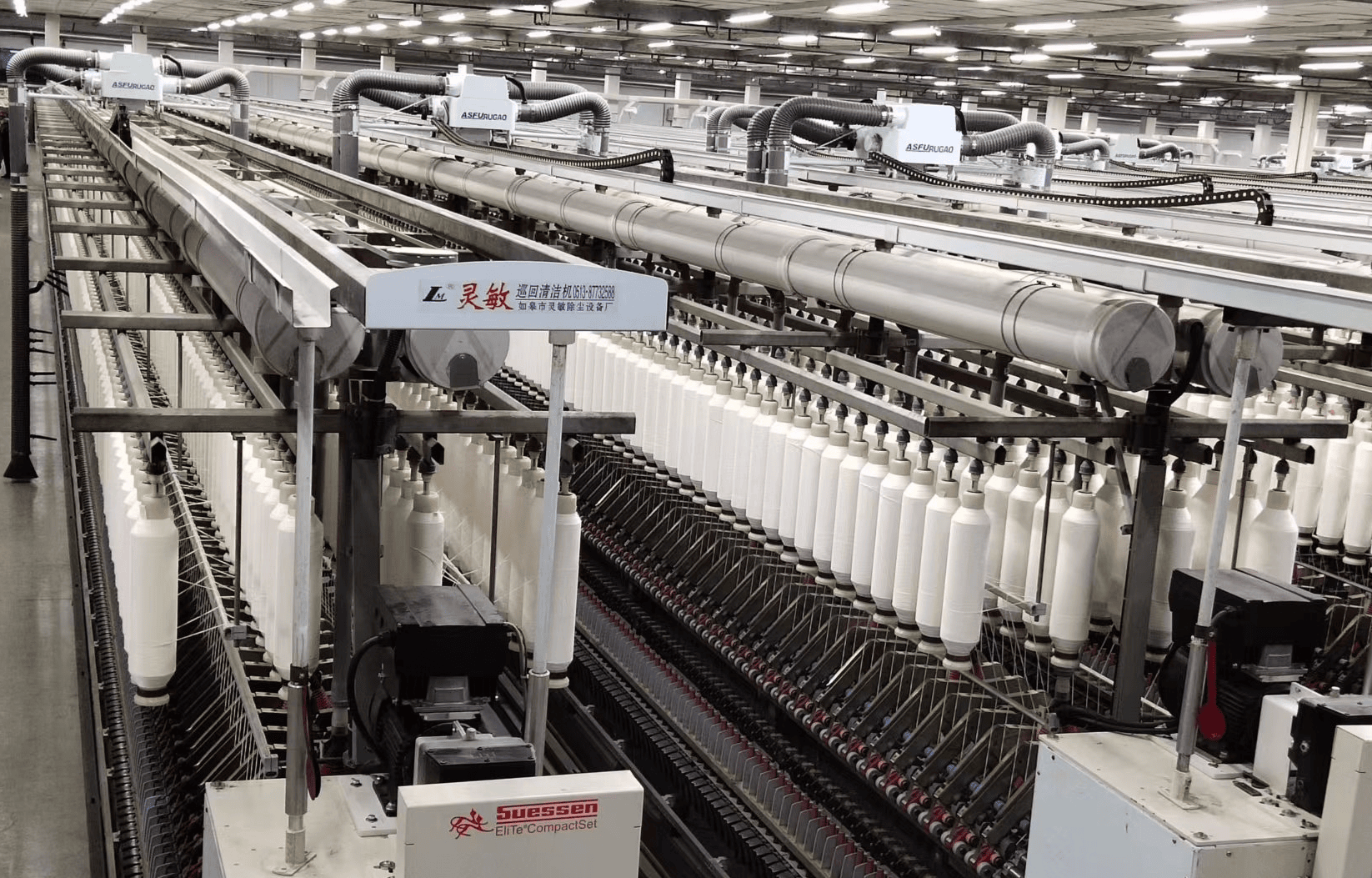

Non-Impact Reversing Mechanism Energy-Saving Blow-Suction Cleaning Machine

Product Application Scope:

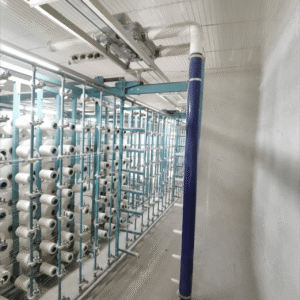

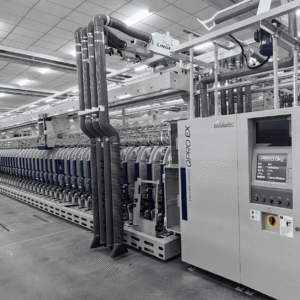

The non-impact reversing mechanism energy-saving blow-suction fan is widely used for automatic reciprocating cleaning in textile machinery such as coarse yarn machines, fine yarn machines, auto-winders, twisters, doubling machines, warping machines, and weaving machines.

Product Features of Non-Impact Reversing Mechanism Energy-Saving Blow-Suction Fan:

Energy-saving:

This product operates with a power configuration of (0.14kw + 0.55kw) 0.69kw, which is approximately 54% more energy-efficient compared to traditional blow-suction fans with a power configuration of 1.5kw. The energy-saving effect is especially significant in fine yarn machines with dual machines, long cars, extended cars, and weaving machines compared to traditional blow-suction fans.

Stable Operation:

Compared to traditional belt-driven blow-suction fans, this product offers smoother operation without the impacts and vibrations associated with reversing in traditional systems. It eliminates issues like unresponsiveness and vibrations caused by wear or delamination of the drive belt, ensuring stable performance throughout the operation.

Intelligent Operation:

This product can be optionally equipped with a PLC intelligent control system or integrated with the main equipment’s PLC system to enable features such as automatic yarn stop, gap running, and cotton-suction pre-stop. These functions meet the varying requirements for blow-suction fan operation during the production process.

Low Operating Cost:

In addition to its energy-saving benefits, this product significantly reduces material consumption compared to traditional belt-driven blow-suction fans, which require regular replacement of components such as drive belts, reversing forks, bearings, and belt wheels. Additionally, when compared to traditional turbine and worm gear blow-suction fans, this product extends the lifespan of electrical components and wiring, further reducing operational costs.

Low Maintenance Cost:

Due to its innovative design, simple mechanism, and low failure rate, this non-impact reversing mechanism energy-saving blow-suction fan reduces labor and material costs for daily maintenance. It improves production efficiency while lowering the overall maintenance burden compared to traditional blow-suction systems.